What Are the Unit Operations in Food Processing?

Food Processing Unit Operations Selector

Select your food product type and processing goals to identify the appropriate unit operations for your food processing line.

Ever wondered what actually happens between a farm field and the snack aisle? The answer lies in a series of well‑defined steps called unit operations. Understanding these steps helps manufacturers design efficient lines, keep products safe, and meet consumer expectations.

Defining the Core Concept

Unit operation is a basic physical or chemical step used in the transformation of raw material into a finished product. In food manufacturing, a unit operation can be as simple as washing a vegetable or as complex as continuous steam sterilization.

Why Unit Operations Matter in Food Processing

Food processors rely on unit operations to achieve three goals: safety, quality, and cost‑effectiveness. Each operation targets a specific change-removing contaminants, altering texture, or extending shelf life. When operations are correctly sequenced, waste drops, energy use falls, and the final food meets regulatory standards.

Major Categories of Food‑Processing Unit Operations

Most food plants organize their workflow into four broad categories:

- Cleaning removes physical debris, soil, and microbes from raw ingredients

- Size reduction grinds, chops, or slices materials to achieve a target particle size

- Thermal treatment applies heat or cold to kill pathogens, inactivate enzymes, or modify texture

- Separation & packaging isolates desired components and encloses the product for distribution

Deep Dive into Individual Unit Operations

1. Cleaning

Cleaning is the first line of defense. Techniques include water immersion, high‑pressure sprays, and chemical sanitizers such as chlorine dioxide. For leafy greens, a counter‑flow washer can achieve >99.9% reduction of E. coli in under two minutes.

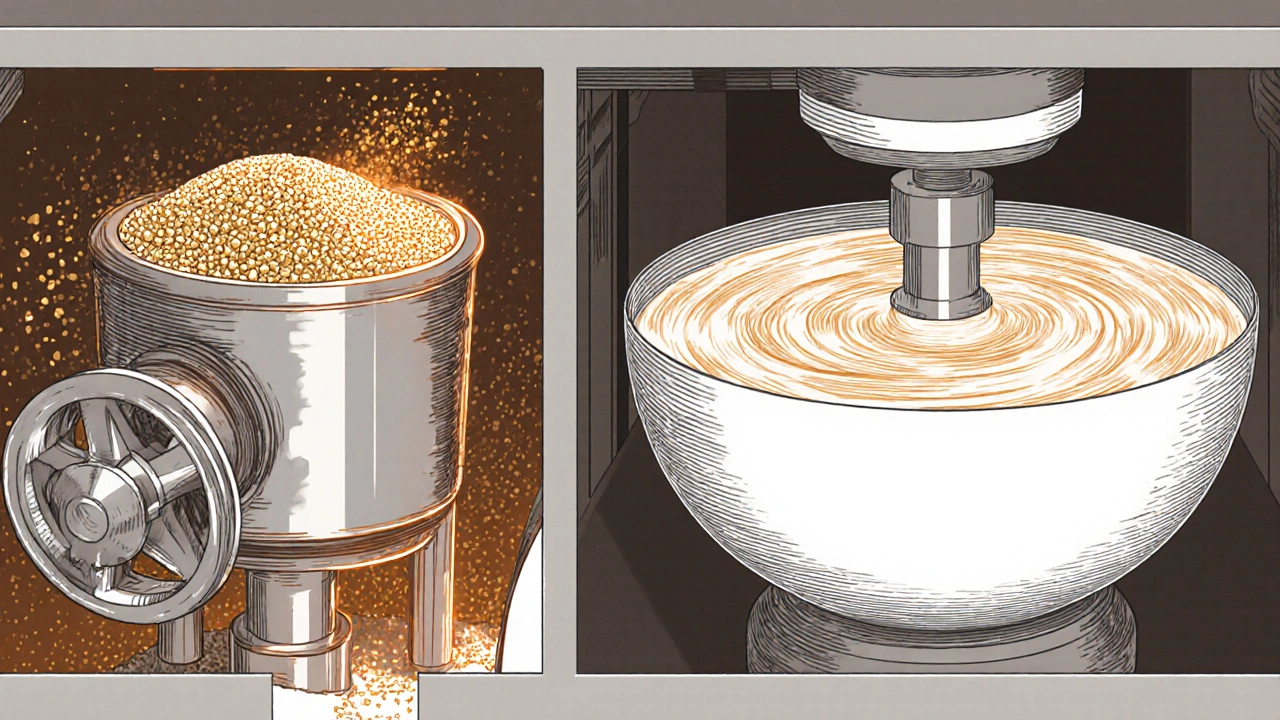

2. Size Reduction (Grinding, Cutting, Sizing)

Typical equipment: hammer mills, slicers, and rotary shredders. Selecting the right screen size influences water absorption in dough, which in turn affects baking time. For meat, a coarse grind (5‑mm) retains juiciness, while a fine grind (1‑mm) is preferred for emulsified products like hot dogs.

3. Mixing & Blending

Mixing uniformly distributes ingredients, promotes chemical reactions, and develops structure. Planetary mixers are common for batter, while ribbon blenders handle dry powders. Proper mixing prevents flour clumping, which can lead to uneven baking.

4. Thermal Treatment

Two sub‑categories dominate:

- Pasteurization uses moderate heat (usually 60‑85°C) for a short time to destroy most vegetative bacteria

- Sterilization applies higher temperatures (121°C or above) for longer periods to achieve commercial sterility

Heat exchangers, steam‑jets, and continuous flow pasteurizers are typical equipment. For milk, a high‑temperature short‑time (HTST) pasteurizer reduces microbial load while preserving flavor.

5. Cooling & Cryogenic Freezing

Rapid cooling (e.g., shock freezing with liquid nitrogen) prevents large ice crystals, preserving texture in berries and fish. Plate freezers and tunnel freezers are selected based on throughput and product shape.

6. Drying

Drying removes moisture to extend shelf life. Common methods include spray drying for dairy powders, drum drying for fruit purees, and freeze‑drying for high‑value probiotic cultures. Energy consumption can be trimmed by integrating waste‑heat recovery from the thermal treatment stage.

7. Fermentation

Fermentation leverages microorganisms to develop flavor, improve nutrition, or produce functional ingredients. Controlled bioreactors maintain temperature, pH, and oxygen levels. Think yogurt (Lactobacillus) or kombucha (symbiotic culture of bacteria and yeast).

8. Separation

After processing, producers often need to separate solids from liquids. Centrifuges, decanters, and membrane filters do the job. For cheese making, a cheese‑cloth or continuous centrifuge removes whey, leaving curds for further pressing.

9. Packaging

Packaging is the final protection barrier. Methods vary from aseptic filling of cartons (for milk) to vacuum sealing of ready‑to‑eat meals. Smart packaging now incorporates oxygen scavengers and RFID tags for real‑time inventory tracking.

Choosing the Right Set of Unit Operations

When designing a new line, ask yourself:

- What safety hazards does the raw material present? (Cleaning, pasteurization)

- What texture or particle size is required? (Sizing, milling)

- Is a functional ingredient needed? (Fermentation, enzymatic treatment)

- How long must the product stay stable? (Drying, packaging)

- What is the target production volume? (Continuous vs. batch equipment)

Mapping answers to the list of unit operations helps avoid over‑engineering and keeps capital costs in check.

Quick Checklist for Setting Up a Food‑Processing Line

- Validate raw‑material specifications and required cleaning intensity.

- Define target particle size and select appropriate size‑reduction equipment.

- Choose thermal treatment level (pasteurization vs. sterilization) based on pathogen risk.

- Plan for heat recovery: connect dryer exhaust to pre‑heat the cleaning water.

- Confirm regulatory compliance for each operation (e.g., HACCP for thermal steps).

- Select packaging that matches shelf‑life expectations and distribution channel.

- Implement real‑time monitoring (temperature, pH, moisture) at critical control points.

Summary Table of Core Unit Operations

| Operation | Main Purpose | Typical Equipment |

|---|---|---|

| Cleaning | Remove contaminants | Water immersion tanks, high‑pressure spray, CIP systems |

| Size Reduction | Achieve target particle size | Hammer mill, slicer, grinder |

| Mixing | Uniform ingredient distribution | Planetary mixer, ribbon blender |

| Thermal Treatment | Kill pathogens / modify texture | HTST pasteurizer, retort, steam‑jet |

| Cooling | Stop microbial growth | Plate freezer, tunnel freezer |

| Drying | Reduce moisture for shelf life | Spray dryer, drum dryer, freeze‑dryer |

| Fermentation | Develop flavor / functional compounds | Bioreactor, fermenter with pH & temp control |

| Separation | Isolate solids or liquids | Centrifuge, decanter, membrane filter |

| Packaging | Provide barrier & convenience | Aseptic filler, vacuum sealer, modified‑atmosphere packager |

Frequently Asked Questions

What is the difference between pasteurization and sterilization?

Pasteurization uses moderate heat (60‑85°C) for a short time to reduce most vegetative bacteria, while sterilization employs higher temperatures (121°C or more) for longer durations to kill all microorganisms, achieving commercial sterility.

How can I reduce energy consumption in a drying operation?

Recover waste heat from the thermal‑treatment stage to pre‑heat the drying air, use multi‑stage dryers, and consider using spray drying for low‑moisture products where the residence time is short.

When is CIP (clean‑in‑place) preferred over manual cleaning?

CIP is ideal for closed systems, high‑throughput lines, and when repeatable, validated cleaning cycles are required to meet HACCP standards.

Can fermentation be scaled up without losing product quality?

Yes, but you must control temperature, pH, oxygen transfer, and mixing intensity. Pilot‑scale trials help fine‑tune the parameters before full‑scale production.

What are the most common packaging failures in food processing?

Seal leakage, oxygen ingress, and incorrect labeling are top issues. Selecting barrier‑grade films, validating sealing parameters, and using automated inspection reduce these risks.