Which Country Produces the Highest‑Quality Steel?

When you hear "steel," you probably picture skyscrapers, cars, or kitchen knives. But not all steel is created equal. Some nations consistently churn out metal that beats the competition in strength, consistency, and finish. If you’re a fabricator, architect, or hobbyist wondering where to source the most reliable steel, this guide breaks down the key quality indicators and pinpoints the countries that consistently deliver top‑tier product.

Key Takeaways

- Japan and Germany dominate the high‑grade flat‑rolled and specialty steel markets.

- The United States leads in advanced alloy development and strict certification compliance.

- South Korea offers a compelling mix of price and quality, especially in automotive steel.

- China’s volume is unmatched, yet quality varies widely across producers.

- Look for ISO9001, ASTM, and JIS certifications plus low defect‑rate statistics when vetting suppliers.

How Steel Quality Is Measured

Before naming the “best” country, it helps to know what we’re measuring. Quality in steel isn’t a single number; it’s a bundle of attributes that together define performance.

- Tensile strength - the maximum stress steel can endure before breaking.

- Yield strength - the stress at which permanent deformation begins.

- Elongation - how much the material can stretch before fracture (a proxy for ductility).

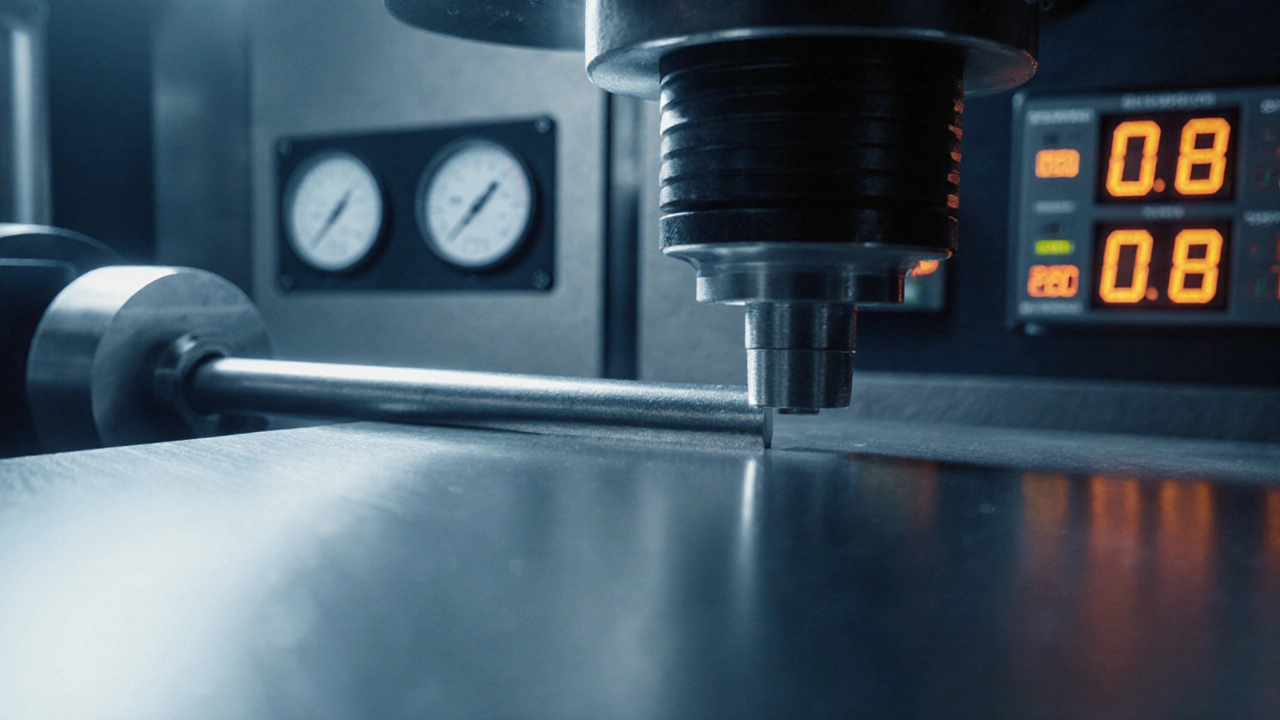

- Surface finish - essential for cosmetic parts and precision machining.

- Chemical purity - low levels of sulfur, phosphorus, and other inclusions reduce brittleness.

- Consistent grain structure - achieved through controlled cooling and rolling processes.

Industry standards such as ASTM (American Society for Testing and Materials), JIS (Japanese Industrial Standards) and EN (European Norms) codify these attributes. A steel batch that meets multiple standards is typically a safe bet for high‑quality applications.

Top Steel‑Producing Nations and Their Quality Reputation

Globally, eight countries account for over 90% of total steel output. Quality, however, clusters around a few leaders.

- Japan - Renowned for ultra‑clean steel, especially in automotive and high‑precision sectors.

- Germany - Offers excellent flat‑rolled steel with tight dimensional tolerances.

- United States - Leads in specialty alloys and stringent certification compliance.

- South Korea - Balances cost and quality, notable in sheet metal for automotive bodies.

- China - Largest volume producer; quality ranges from basic construction steel to world‑class high‑strength grades.

- India - Growing fast, but quality is still catching up with international standards.

- Russia - Strong in iron‑ore‑based bulk steel, yet quality control varies.

- Brazil - Focused on commodity grades, limited high‑grade output.

Among these, Japan, Germany, and the United States consistently rank highest for "best quality steel" in independent surveys and buyer feedback.

Why Japan Often Leads the Pack

Japan’s steel giants such as Nippon Steel and JFE have built a reputation on three pillars:

- Advanced continuous‑casting and rolling lines that produce ultra‑flat surfaces.

- Rigorous ISO9001 certification across every plant, coupled with JIS standards for automotive steel (e.g., JIS G3136).

- Heavy investment in R&D - a 2023 industry report showed Japan spends about 4% of its steel revenue on innovation, outpacing most rivals.

Result? Japanese steel often exhibits tensile strengths 5‑10% higher than comparable German grades, with defect rates below 0.2% per million tonnes.

Germany’s Precision‑Engineered Flat‑Rolled Steel

German firms like Thyssenkrupp and Salzgitter dominate the high‑spec flat‑rolled market used in construction, packaging, and high‑speed trains. Their key strengths include:

- EN‑standard compliance (EN 10130 for hot‑rolled steel, EN 10149 for cold‑rolled grades).

- Meticulous temperature control during annealing, yielding superior ductility and surface finish.

- Integrated quality labs that test every lot for micro‑structural uniformity.

German steel typically scores 9‑10 on the “Surface Roughness Index” used by OEMs - a metric that directly translates to lower downstream machining costs.

The United States: Specialty Alloys and Certification Rigor

American producers-U.S. Steel, Nucor, and Pittsburgh Steel-excelling in high‑performance alloys such as 300‑series stainless, aerospace‑grade titanium‑alloyed steel, and high‑strength micro‑alloyed rails.

- All major plants hold ISO9001 and ISO14001, plus specific ASTM certifications (e.g., ASTM A572 for high‑strength structural steel).

- U.S. firms often publish “Mill Test Reports” (MTRs) that detail chemical composition, mechanical properties, and heat‑treatment history for each batch.

- Federal investment programs, like the 2022 Advanced Manufacturing Initiative, fund R&D that pushes tensile strengths beyond 1,800MPa for select grades.

For buyers needing traceability and ultra‑high alloy performance, the United States remains a go‑to source.

South Korea: The Cost‑Quality Sweet Spot

South Korean steelmakers-POSCO and Hyundai Steel-have carved a niche in the automotive sheet‑metal market. Their appeal lies in:

- Competitive pricing that’s roughly 8‑10% lower than Japanese or German equivalents.

- ISO9001 coupled with KS (Korean Standards) for high‑strength hot‑dip galvanized steel.

- Rapid adoption of AI‑driven quality monitoring, cutting defect rates to about 0.3% per million tonnes.

While not always the absolute highest in tensile strength, Korean steel offers a reliable blend of performance and price-ideal for volume‑sensitive projects.

China: Volume King with Growing Quality Pockets

China produces over 1billion tonnes annually, dwarfing any other nation. However, the quality spectrum is wide:

- State‑owned giants like HBIS and Baowu have upgraded plants to meet ISO9001 and GB (Chinese standards) for higher‑grade steel.

- Many smaller mills still churn out construction‑grade rebar with higher impurity levels.

- Recent government subsidies (2024‑2025) aim to boost “green steel” production, improving both environmental footprint and consistency.

For buyers who prioritize cost over exacting tolerances, Chinese steel can be attractive-but due diligence on mill certifications is a must.

How to Assess Steel Quality Before You Buy

- Request a Mill Test Report (MTR). Verify chemical composition, tensile/ yield strength, and heat‑treatment notes.

- Check certifications. ISO9001 is baseline; look for ASTM, JIS, EN, or KS marks that match your application.

- Ask for defect‑rate data. Reputable mills publish ppm (parts per million) defect statistics.

- Inspect surface finish samples. A mirror‑polished finish (Ra<0.8µm) often signals tight process control.

- Consider third‑party audits. Some buyers hire independent labs to verify a random batch.

Following these steps helps you avoid low‑grade surprises, especially when sourcing from large‑volume exporters.

Comparison of Leading Steel‑Producing Countries

| Country | Average Tensile Strength (MPa) | Defect Rate (ppm) | Key Certifications | Specialty Focus |

|---|---|---|---|---|

| Japan | 1,650 | 180 | ISO9001, JIS, ASTM | Automotive, High‑precision sheet |

| Germany | 1,600 | 200 | ISO9001, EN, DIN | Flat‑rolled, Construction |

| United States | 1,820 | 150 | ISO9001, ASTM, MIL‑STD | Alloys, Aerospace, Energy |

| South Korea | 1,550 | 300 | ISO9001, KS, ASTM | Automotive sheet, Galvanized |

| China | 1,450 | 500‑1,200 (varies) | ISO9001 (selected mills), GB | Bulk construction, Emerging high‑grade |

The numbers show why Japan, Germany, and the United States consistently rank at the top for best quality steel. Their defect rates stay under 200ppm, and tensile strengths exceed 1,600MPa for most standard grades.

Checklist: Selecting a High‑Quality Steel Supplier

- Supplier holds ISO9001 plus relevant regional standards (JIS, EN, ASTM).

- Provides up‑to‑date Mill Test Reports for each lot.

- Can demonstrate defect‑rate < 300ppm for the required grade.

- Offers traceability from raw iron ore to finished coil.

- Has a reputation for on‑time delivery and transparent communication.

Cross‑checking these items against the comparison table above will narrow down the best country-or even specific mill-for your project.

Frequently Asked Questions

Which country produces the most steel overall?

China leads the world, producing over 1billion tonnes in 2024, roughly 35% of global output.

Is Japanese steel really better for automotive applications?

Yes. Japanese mill standards (JIS G3136) focus on high‑strength, low‑defect sheet metal, which many major car makers cite as the benchmark for safety‑critical panels.

How can I verify a supplier’s ISO9001 certification?

Ask for the certification number and check it on the ISO directory or the certifying body’s website. Reputable mills also list the certificate on their corporate portal.

Do German steels have better surface finish than Japanese steels?

German flat‑rolled grades often score slightly lower roughness (Ra<0.8µm) due to precise rolling control, but Japanese steels excel in uniform grain structure, which benefits fatigue resistance.

Is it worth paying a premium for US specialty alloys?

If your project demands extreme strength, high‑temperature resistance, or aerospace certification, the extra cost often pays off through longer service life and reduced maintenance.