Which Is the Fabric Capital of India? The Truth About India’s Textile Hub

Textile Production Comparison Tool

Compare Surat's textile production volume with other major Indian textile hubs. See how Surat's production scale compares to other cities in terms of volume, jobs, and economic impact.

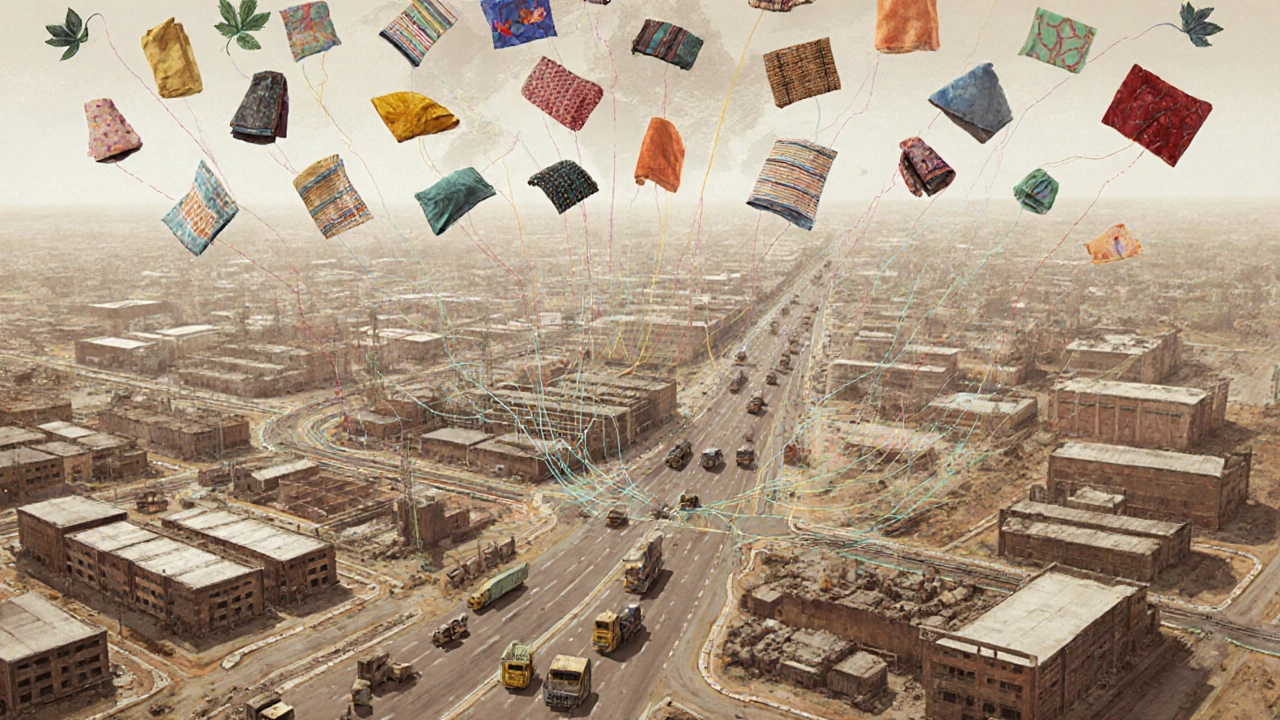

When you think of Indian fabrics, what comes to mind? Banarasi silk? Handloom khadi? Chanderi? All of these are famous-but none of them are the heart of India’s fabric production. The real answer lies in a city that doesn’t always make headlines, but produces more fabric than any other place on the planet: Surat.

Surat Isn’t Just a City-It’s a Fabric Machine

Surat, in Gujarat, churns out over 80% of India’s synthetic fabric and 70% of its cotton fabric. That’s not a guess. It’s a number confirmed by the Textile Ministry and the Surat Textile Market Association. Every day, more than 15,000 weaving units, 3,000 dyeing plants, and 2,000 printing units operate non-stop. The city doesn’t just make fabric-it makes it fast, cheap, and in massive volumes.

Walk into the Sarthana Nature Park area or the New Textile Market, and you’ll see warehouse after warehouse stacked with bolts of fabric. Some are plain polyester, others are printed with intricate designs for export to the U.S., Europe, and Southeast Asia. You won’t find tourists here. You’ll find buyers from Bangladesh, Kenya, and Nigeria negotiating prices in Hindi, Gujarati, and Urdu.

Why Surat? The Hidden Advantages

Surat didn’t become the fabric capital by accident. It happened because of three things: access to raw materials, skilled labor, and decades of specialization.

First, the city sits close to the major petrochemical hubs of Dahej and Vadodara. That means polyester chips, the base for most synthetic fabrics, arrive cheap and fast. No need to ship raw materials from far away. Second, Surat has generations of families who’ve lived and worked in textiles. A 16-year-old here can thread a loom better than most engineers in other cities. Third, the entire supply chain is local. You need dye? There’s a supplier 500 meters away. Need a new needle for your machine? It’s delivered by 8 a.m.

Compare that to Bangalore or Coimbatore, where textile units are scattered and supply chains are fragmented. In Surat, everything is clustered. That’s why turnaround time for bulk orders is just 7-10 days. In other parts of India, it’s often 3-4 weeks.

What Kind of Fabric Comes Out of Surat?

Surat doesn’t make just one type of fabric. It makes hundreds. Here’s what you’ll find:

- Polyester satin - Used in bridal wear, home decor, and fashion labels worldwide

- Chiffon and georgette - Lightweight, flowy fabrics for sarees and dresses

- Stretchable fabrics - For activewear and shapewear

- Printed and embroidered fabrics - Custom designs for global brands like Zara, H&M, and Forever 21

- Cotton blends - Affordable, breathable fabrics for everyday wear

Surat also leads in digital printing. Machines here can print 1,000 meters of fabric in a single run with zero waste. That’s why global fashion brands outsource their entire print runs to Surat instead of setting up their own plants.

Surat vs. Other Textile Hubs in India

Other cities have their strengths, but none match Surat’s scale:

| City | Primary Fabric Type | Annual Production (in metric tons) | Export Share | Specialization |

|---|---|---|---|---|

| Surat | Synthetic & Cotton Blends | 12 million+ | 65% | High-volume, low-cost, fast turnaround |

| Bhagalpur | Tussar Silk | 80,000 | 15% | Handwoven, artisanal silk |

| Varanasi | Banarasi Silk | 120,000 | 8% | Luxury handloom, intricate zari work |

| Coimbatore | Cotton Yarn & Fabric | 2.5 million | 20% | Spinning, quality cotton |

| Kota | Kota Doria | 40,000 | 5% | Lightweight cotton for summer wear |

Surat’s numbers dwarf the rest. Bhagalpur and Varanasi make beautiful, high-end fabrics-but they’re artisanal. They can’t scale. Surat’s machines run 24/7. A single unit in Surat can produce more fabric in a week than a whole village in Varanasi does in a year.

The Real Impact: Jobs, Economy, and Global Reach

Surat’s textile industry employs over 3 million people directly and another 2 million indirectly. That’s more than the population of many countries. The city’s textile exports hit $18 billion in 2024, making it India’s largest textile export hub.

It’s not just about money. It’s about dignity. In Surat, a young woman working in a printing unit can earn ₹25,000 a month-more than the national average for urban workers. Many start as helpers, learn machine operation, and become supervisors in five years. The industry doesn’t just make fabric-it builds careers.

Global retailers know this. When H&M needs 50,000 meters of printed polyester for its summer collection, they don’t go to China. They go to Surat. Why? Because the quality is better, the lead time is shorter, and the cost is 30% lower.

What’s Changing in Surat Today?

Surat isn’t resting. The city is upgrading. New automated looms from Germany and Italy are replacing old machines. Solar-powered dyeing units are cutting pollution. The government’s PM MITRA scheme is building five new textile parks near Surat, with one already operational.

Young entrepreneurs are launching eco-friendly fabric lines-organic cotton, recycled polyester, waterless dyeing. One startup in Surat now makes fabric from recycled plastic bottles. They sell it to European brands that need sustainable materials.

Even the traditional weavers are adapting. Many now use digital design software to create patterns instead of drawing them by hand. The old and the new are working side by side.

Visiting Surat’s Textile Market? Here’s What to Know

If you’re a buyer or a curious traveler, Surat’s market is overwhelming-but worth it. Go to the New Textile Market (near Sarthana) or the Old Textile Market. Bring cash. Many small traders don’t accept cards. Don’t ask for prices in dollars-deal in INR. Start small. Buy 5 meters of fabric before placing a bulk order.

Don’t expect luxury showrooms. This isn’t Milan. It’s raw, loud, and real. But if you want to see how the world’s clothes are made, this is where you need to be.

Is Surat the Only Fabric Capital? What About Other Cities?

Some people argue that Varanasi or Coimbatore should be called the fabric capital. But that’s mixing up art with industry. Varanasi makes the most beautiful silk sarees. Coimbatore makes the best cotton yarn. But Surat makes the fabric that ends up on the backs of billions.

Think of it this way: If India’s textile industry were a car, Surat would be the engine. The others are the wheels, the seats, the lights. They matter-but without the engine, the car doesn’t move.

Is Surat the only fabric capital of India?

Yes, Surat is the only city that qualifies as India’s fabric capital based on volume, speed, and global reach. Other cities like Varanasi and Bhagalpur are known for high-end, handcrafted textiles, but they produce a fraction of what Surat does. Surat dominates in synthetic and cotton fabric production, supplying over 80% of India’s textile output.

What types of fabric are made in Surat?

Surat produces a wide range of fabrics, including polyester satin, chiffon, georgette, stretch fabrics, printed cotton blends, and embroidered textiles. It’s especially known for digital printing, where it leads India in volume and precision. The city also produces recycled and eco-friendly fabrics for global brands.

How does Surat compare to China in fabric production?

Surat is now a stronger competitor than China for mid-range, fast-turnaround fabric orders. While China still leads in ultra-low-cost mass production, Surat offers better quality control, faster delivery (7-10 days vs. 30+ days), and easier communication. Many global brands have shifted bulk orders from China to Surat in the last five years.

Can I buy fabric directly from Surat as a small buyer?

Yes. While most traders focus on bulk orders (500+ meters), many shops in the New Textile Market sell as little as 1-5 meters. Bring cash, be ready to negotiate, and don’t be afraid to ask for samples. Many sellers are used to dealing with small designers and startups.

Why is Surat’s fabric so cheap?

Surat’s low prices come from three factors: proximity to raw material suppliers, a massive pool of skilled labor willing to work for moderate wages, and a fully integrated local supply chain. There’s no need to ship materials across the country. Everything-from dye to needles-is available within a few kilometers.

Final Thought: It’s Not Just Fabric-It’s a System

Surat’s power isn’t in its machines or its workers. It’s in the system. Every piece of fabric that leaves Surat is the result of a tightly woven network of families, small businesses, logistics providers, and tech upgrades-all working together. No other city in India has built that kind of ecosystem.

If you want to understand modern Indian manufacturing, don’t look at Silicon Valley or Bengaluru. Look at Surat. That’s where the real fabric of India is made.