US Factory Output: What’s Really Happening in American Manufacturing

When we talk about US factory output, the total value of goods produced by American manufacturing plants in a given period. Also known as industrial production, it’s the heartbeat of the nation’s economy—tracking everything from steel beams to smartphones. It’s not just a number on a chart. It tells you if factories are running full speed, sitting idle, or shifting what they make. And right now, that story is more complex than headlines suggest.

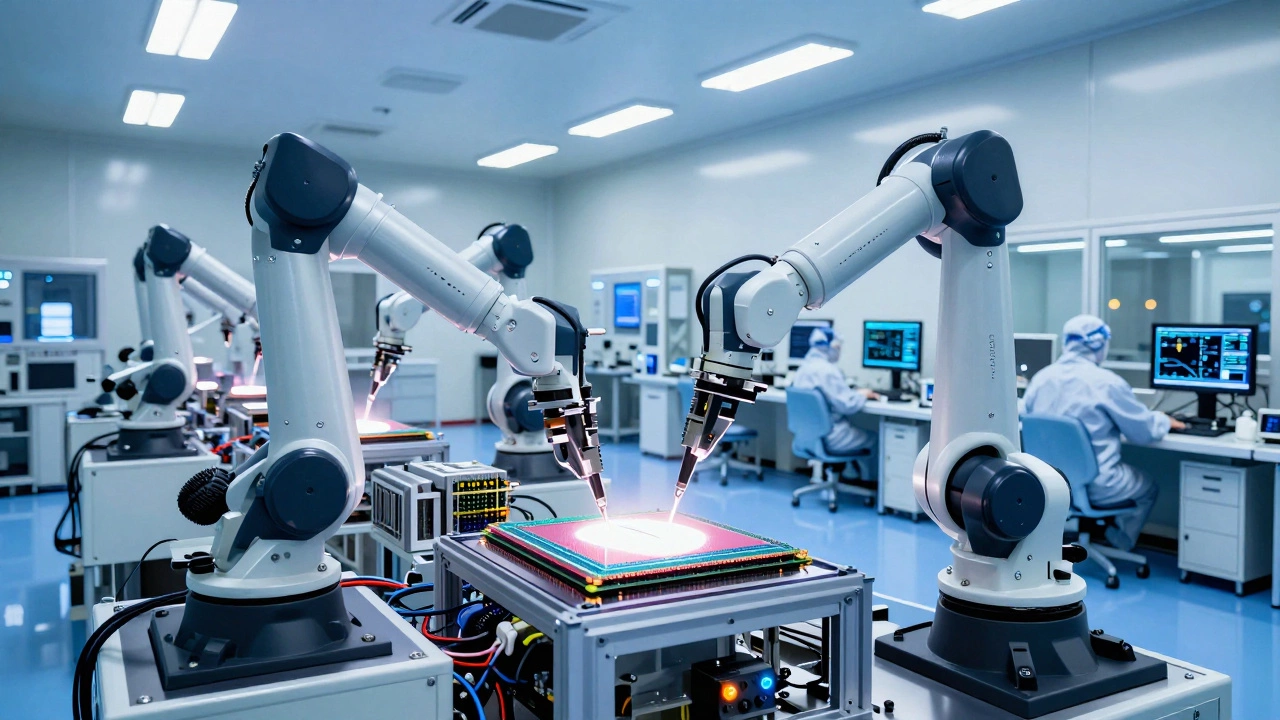

US factory output doesn’t mean everything is made in the US anymore. Factories still turn out cars, medical devices, and semiconductors—but the mix has changed. A decade ago, you’d see big gains in electronics and appliances. Today, you see more growth in defense equipment, renewable energy parts, and specialized machinery. Meanwhile, consumer goods like clothing and basic plastics are mostly imported. The real shift isn’t in volume—it’s in factory capacity, the maximum amount of goods a factory can produce under normal operating conditions. Many plants now run leaner, smarter, and with fewer workers. Automation, AI-driven quality checks, and just-in-time supply chains have replaced the old model of stacking workers on assembly lines.

What’s driving this? manufacturing in the US, the process of transforming raw materials into finished goods within American borders is no longer about cheap labor. It’s about speed, reliability, and avoiding global supply chain shocks. After the pandemic, companies realized they couldn’t depend on factories halfway across the world. So they’re bringing some production back—especially for critical items like pharmaceuticals, batteries, and chips. This isn’t a full return to the 1990s. It’s a new kind of manufacturing: smaller batches, higher tech, and focused on national security as much as profit.

And it’s not just big corporations doing this. Small and mid-sized factories are adapting too. One in Indiana now makes custom parts for drones used in agriculture. Another in Ohio retools every six months to meet new demands from local solar installers. These aren’t factory giants. But together, they’re reshaping what US factory output looks like today.

There’s a myth that American manufacturing is dying. It’s not. It’s changing. The jobs are fewer but more skilled. The products are more advanced. And the focus is shifting from quantity to resilience. If you’re in business, in policy, or just curious about how things get made—you need to understand this new reality. Below, you’ll find real stories from inside US factories: what’s being made, why some products failed, how supply chains are being rebuilt, and what’s next for the people who keep the machines running.

Is Manufacturing Down in the US? Real Data on Trends, Jobs, and Government Help

US manufacturing output is at record highs despite fewer workers. Government programs like the CHIPS Act and Inflation Reduction Act are driving a tech-driven revival in semiconductors, batteries, and clean energy production.

Read More