Is Manufacturing Still Profitable in 2026? Real Numbers, Real Stories

Manufacturing Profit Calculator

Your Manufacturing Parameters

Key Metrics

0%

$0.00

$0.00

How to Maximize Profit

Key Insight: Small manufacturers see highest profits when they focus on niche products with specialized value (like the titanium implants example from the article). Local sourcing and certification can increase margins by 15-25%.

Pro Tip: The article shows that automation can increase profit per unit by 300% (like the bracket manufacturer example). Start with just 1-2 automated processes.

Manufacturing still makes money-just not the way it used to. If you’re thinking about starting a manufacturing business in 2026, you’ve probably heard the old stories: factories closing, jobs moving overseas, automation replacing workers. But here’s the truth most people miss: manufacturing is more profitable than ever-if you know where to look and how to play the game.

Profit Margins Are Tighter, But Higher in Niche Areas

Mass-producing cheap plastic toys or basic T-shirts? That’s a race to the bottom. Margins there are often under 5%. But look at specialized manufacturing-custom medical devices, high-precision metal parts for drones, or biodegradable packaging for organic food brands-and margins jump to 25-40%. The key isn’t volume anymore. It’s value.

In Sydney, a small workshop called PrecisionCore makes custom titanium implants for orthopedic surgeons. They produce fewer than 500 units a year. Each one sells for $8,000. Their cost? Around $4,200. That’s a 90% gross margin. They don’t compete with factories in China. They compete on expertise, speed, and compliance. And they’re hiring.

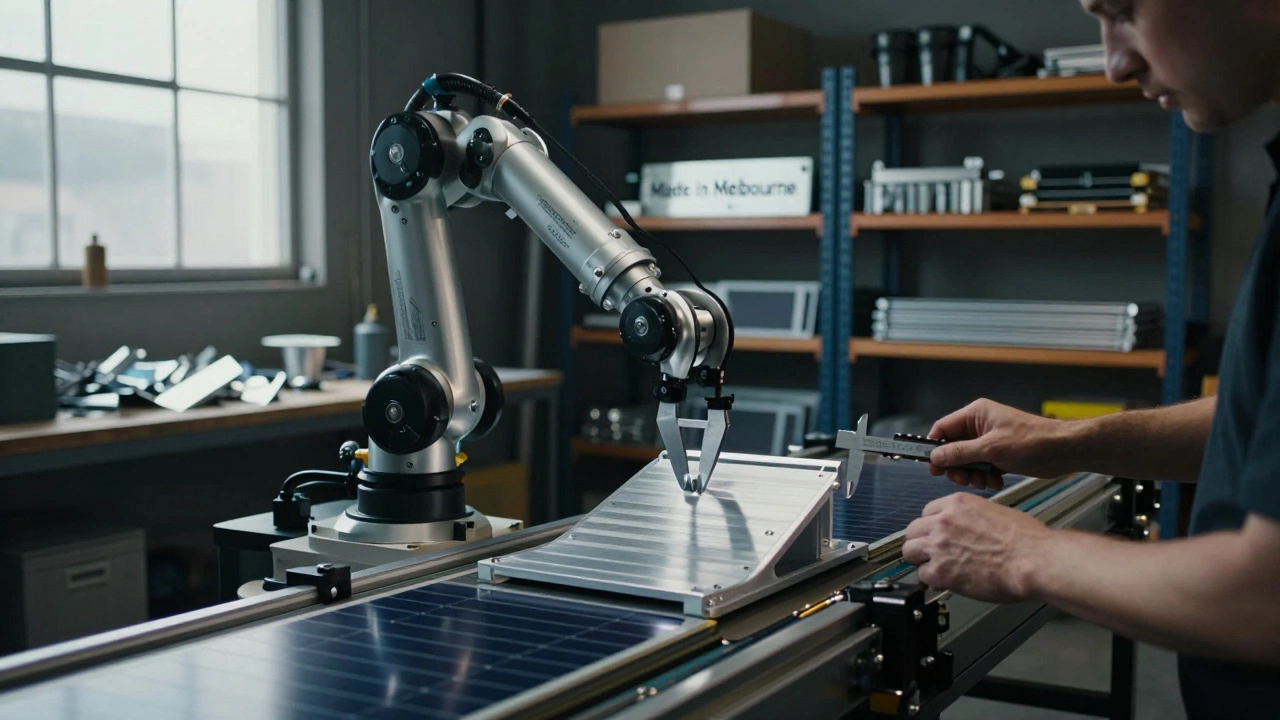

Automation Isn’t Killing Profit-It’s Creating It

You hear automation and think job losses. But for small manufacturers, it’s the opposite. A $15,000 CNC machine can replace three workers doing repetitive tasks. It doesn’t sleep. It doesn’t call in sick. And it cuts material waste by 30%.

Take a Melbourne-based company making custom aluminum brackets for solar panel installers. Before automation, they spent 4 hours per bracket. Now, with a single CNC and a robotic arm, they make 12 in the same time. Labor costs dropped from $60 per unit to $8. Material cost stayed the same. Output doubled. Profit per unit? Up 300%.

The trick? Don’t automate everything. Automate the boring, repetitive, error-prone parts. Keep the human touch for design, quality control, and customer communication.

Local Sourcing Is a Secret Profit Driver

Global supply chains are still broken. A shipment from Vietnam can take 60 days. A delay? You lose customers. But if you source materials locally-even in Australia-you cut lead times to 3-5 days. That’s a competitive edge no offshore factory can match.

One Perth-based manufacturer makes eco-friendly food containers from sugarcane pulp. They buy waste pulp from local sugar mills, process it in their own facility, and sell to cafes and restaurants across Western Australia. No shipping costs. No customs delays. No plastic tariffs. Their profit margin? 37%. And their customers love that it’s local.

Local doesn’t mean small-scale. It means agile. It means you can respond to demand changes in days, not months.

Regulations Are a Barrier-Unless You Turn Them Into a Brand

Environmental rules, safety standards, and product certifications sound like headaches. But smart manufacturers use them as marketing tools.

A Brisbane company producing stainless steel kitchenware got ISO 14001 certification for environmental management. They didn’t just slap a sticker on the box. They made a video showing how their factory recycles 98% of its metal scraps. They partnered with zero-waste influencers. Sales jumped 65% in six months.

Another example: a Sydney-based producer of baby bottles made from medical-grade silicone. They passed FDA and EU safety tests. Their packaging says: “Tested in 12 countries. Approved by 5 health agencies.” Parents don’t just buy a bottle. They buy peace of mind. And they pay $28 for it-twice the price of generic brands.

Start Small. Start Smart. Start Now.

You don’t need a factory the size of a football field. You need:

- A clear niche (not “I make things,” but “I make waterproof LED panels for aquariums”)

- A reliable supplier for raw materials (preferably local)

- One automated machine you can pay off in 18 months

- A direct sales channel (your own website, Etsy, or B2B platform)

- A story that matters to your customer

One man in Adelaide started with a $7,000 3D printer and a $2,000 resin tank. He designed custom replacement parts for vintage motorcycles. No inventory. No warehouse. He prints on demand. Customers upload photos. He sends the part in 3 days. He makes $120 per part. He works 20 hours a week. He’s profitable. And he’s just getting started.

The Real Cost of Not Manufacturing

What’s more dangerous than investing in manufacturing? Not investing at all.

Businesses that outsource everything lose control. Quality drops. Delivery times stretch. Customers get frustrated. And when they leave, they don’t come back.

Look at the rise of “made locally” labels in Australia. In 2023, 68% of consumers said they’d pay more for products made in Australia. By 2025, that number hit 79%. It’s not a trend. It’s a shift in values.

Manufacturing isn’t dying. It’s evolving. The old model-big, cheap, mass-produced-is fading. The new model-small, smart, specialized, local-is thriving.

What’s Stopping You?

Let’s be honest. The biggest barrier isn’t money. It’s mindset. People think manufacturing means smokestacks and hard hats. But today, it’s code on a screen, a CNC machine humming in a garage, and a founder answering emails at 8 p.m.

If you can solve a real problem for a specific group of people-whether it’s replacing a broken part, making safer packaging, or building a custom tool-you can build a profitable manufacturing business. You don’t need a degree. You don’t need millions. You just need to start.

Start with one product. One customer. One machine. And build from there.

Is manufacturing still profitable in Australia in 2026?

Yes-but only if you focus on high-value, niche products. Mass production with low margins is dying. But businesses making custom medical parts, eco-friendly packaging, or specialized industrial components are seeing profit margins of 25-40%. Local sourcing, automation, and strong branding are key drivers.

What are the most profitable types of small-scale manufacturing?

The top profitable areas in 2026 include: custom medical devices, precision metal components for drones and robotics, biodegradable packaging for food brands, specialty kitchenware with certifications (FDA, EU), and on-demand 3D-printed replacement parts. These all have low competition, high margins, and repeat customers.

Can I start manufacturing with under $20,000?

Absolutely. A used CNC machine ($8,000-$12,000), a 3D printer ($2,000), basic tools ($1,500), and raw materials ($3,000) can get you started. Many successful manufacturers begin in garages or small workshops. The key is starting with one product, not ten.

Do I need to hire a lot of staff to be profitable?

No. Many profitable manufacturers operate with just one or two people. Automation handles production. The owner focuses on design, customer service, and sales. Outsourcing packaging and shipping is common. Labor isn’t your biggest cost-waste, delays, and poor quality are.

How do I find customers for my manufactured product?

Start with direct channels: your own website, Etsy, Shopify, or B2B marketplaces like ThomasNet. Target niche communities-Facebook groups, Reddit threads, trade shows for your industry. Offer samples. Collect testimonials. Word-of-mouth and repeat buyers are your best growth engine.

Are government grants available for small manufacturers in Australia?

Yes. Programs like the Modern Manufacturing Initiative and state-based innovation grants offer funding for automation, R&D, and export readiness. Some grants cover up to 50% of equipment costs. Check your state’s department of industry website-most have dedicated support for small manufacturers.

Next Steps: What to Do Today

Don’t wait for the perfect plan. Start with these three actions:

- Identify one problem you can solve with a physical product-something people are tired of buying from overseas.

- Find one local supplier for materials. Call them. Ask for samples.

- Buy or rent one automated tool. Even a $3,000 laser cutter or CNC router can change everything.

Manufacturing in 2026 isn’t about scale. It’s about speed, specificity, and sincerity. The market is waiting-for the next person who’s willing to make something real, right here, right now.