What Is the Number 1 Under Plastic Bottles? Understanding Resin Identification Codes

Plastic Resin Code Checker

Ever picked up a water bottle, flipped it over, and seen that little triangle with a "1" inside? You’re not alone. Millions of people see this symbol every day but rarely stop to ask: what is the number 1 under plastic bottles? It’s not a batch number, a expiration code, or a random stamp. It’s a resin identification code - and it tells you everything you need to know about what that bottle is made of, how to recycle it, and why it’s the most common plastic on the planet.

What the Number 1 Actually Means

The number 1 inside the chasing arrows triangle stands for Polyethylene Terephthalate, commonly called PET or PETE. This is the same material used in over 70% of all plastic beverage bottles in the U.S. and Europe. It’s lightweight, clear, strong, and doesn’t let gases escape easily - which is why soda, water, juice, and even cooking oil come in PET containers.PET was first developed in the 1940s, but it didn’t become popular for bottles until the late 1970s. That’s when Coca-Cola switched from glass to PET for its 20-ounce bottles. The shift saved money, reduced breakage, and made shipping easier. Today, over 500 billion PET bottles are produced globally each year. That’s about 67 bottles per person on Earth.

Why PET Is the Go-To Plastic for Drinks

Not all plastics are made equal. PET has a unique set of properties that make it ideal for holding liquids:- It’s food-safe and approved by the FDA and EFSA for direct contact with drinks

- It’s highly recyclable - more than 60% of PET bottles collected in the U.S. get turned into new products

- It’s shatter-resistant, which makes it safer than glass

- It’s lightweight - a 500ml PET bottle weighs just 15-20 grams, compared to 300+ grams for glass

- It blocks carbon dioxide well, so soda stays fizzy

Manufacturers love PET because it’s cheap to produce and easy to mold into different shapes. A single machine can produce 10,000 bottles per hour. That’s why you’ll find PET bottles everywhere - from gas stations to hotel minibars to vending machines in rural villages.

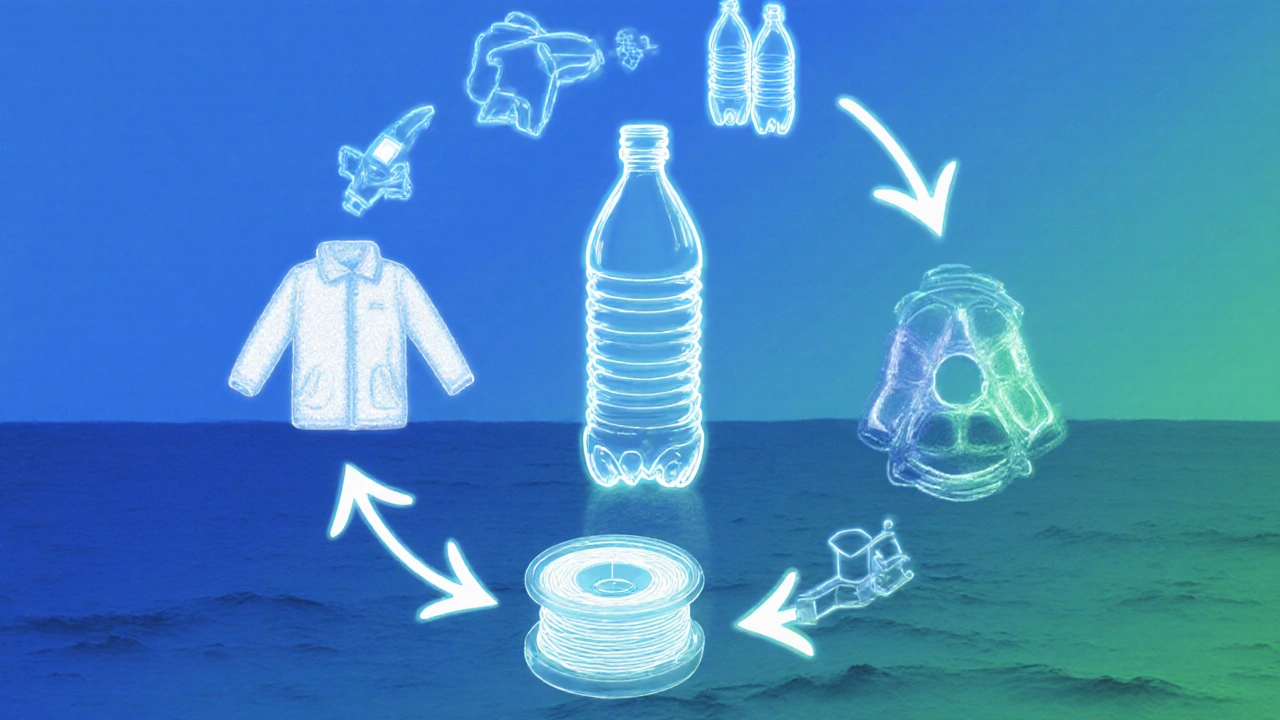

How PET Gets Recycled - And Where It Goes

The number 1 isn’t just a label. It’s a signal to recycling centers: “This is easy to process.” When you toss a PET bottle into the blue bin, here’s what happens:- It’s collected and sorted by resin type using near-infrared scanners

- Labels and caps are removed (caps are usually PP, or #5 plastic)

- The bottles are crushed into flakes

- Flakes are washed, dried, and melted into pellets

- Pellets are sold to manufacturers to make new products

Most recycled PET becomes fiber for clothing - think fleece jackets, sportswear, and carpeting. In fact, over 60% of recycled PET goes into textiles. But it’s also used to make new bottles (called rPET), food containers, strapping bands, and even 3D printer filament.

Some companies, like Coca-Cola and PepsiCo, now use 50% recycled PET in their bottles. Nestlé’s Poland Spring brand launched a bottle made entirely from 100% rPET in 2023. The technology exists. The challenge is getting enough clean, sorted material back into the system.

What You Can’t Recycle With PET

Not all bottles with a #1 are recyclable. Here’s what to avoid:- Containers that held motor oil, paint, or chemicals - even if they have a #1, they’re contaminated

- Bottles with food residue - rinse them out before recycling

- Multi-layered packaging - like juice boxes or foil-lined drink pouches - these aren’t PET

- Broken or crushed bottles - they jam sorting machines

Even if a bottle has the number 1, if it’s dirty or mixed with other plastics, it can ruin an entire batch of recyclables. One greasy yogurt cup can contaminate 1,000 PET bottles. That’s why local recycling rules matter - check your city’s guidelines before tossing anything in.

Other Numbers You’ll See on Plastic

The number 1 is just the first of seven resin codes. Here’s what the others mean:| Code | Plastic Type | Common Uses | Recyclability |

|---|---|---|---|

| 1 | PET or PETE | Beverage bottles, food jars | High - widely accepted |

| 2 | HDPE | Milk jugs, detergent bottles | High - widely accepted |

| 3 | PVC | Pipes, vinyl siding, shower curtains | Low - rarely recycled |

| 4 | LDPE | Plastic bags, squeeze bottles | Medium - often requires drop-off |

| 5 | PP | Yogurt tubs, bottle caps, straws | Medium - growing acceptance |

| 6 | PS | Styrofoam cups, takeout containers | Low - hard to recycle |

| 7 | Other | Biodegradable plastics, polycarbonate, mixed resins | Very low - often not recyclable |

Only codes 1 and 2 are accepted in nearly every curbside recycling program. Code 5 (PP) is catching up, thanks to companies like TerraCycle and Preserve. But codes 3, 6, and 7? Most landfills treat them as trash.

Why the Number 1 Matters for the Environment

Plastic pollution isn’t just about litter. It’s about systems. PET bottles make up nearly 30% of all plastic waste in oceans and rivers. But because PET is so widely collected and recycled, it has one of the highest recovery rates of any plastic - about 29% in the U.S. and over 50% in countries like Germany and Japan.That’s why recycling your PET bottle isn’t just good practice - it’s one of the most effective individual actions you can take to reduce plastic waste. Every bottle you recycle saves energy: producing a new PET bottle from recycled material uses 70% less energy than making it from raw oil.

And here’s something most people don’t know: a single recycled PET bottle can become a new bottle in as little as 30 days. That’s the speed of a circular economy in action.

What You Can Do Today

You don’t need to be an expert to make a difference. Here’s what works:- Always rinse your PET bottles before recycling

- Leave the cap on - modern sorting systems handle them now

- Don’t crush bottles unless your local program asks for it

- Choose products in rPET packaging when you can

- Support brands that use recycled content - it creates demand

There’s no magic solution to plastic waste. But understanding the number 1 under plastic bottles is a simple, powerful first step. It turns a confusing symbol into a tool for change.

Is the number 1 on plastic bottles the same everywhere?

Yes. The resin identification code system was created by the Society of the Plastics Industry (now the Plastics Industry Association) in 1988 and is used globally. Whether you’re in India, Brazil, or Germany, a #1 means PET. The shape of the triangle and the numbering system are standardized by ISO 11469, so it’s consistent across countries.

Can you microwave plastic with a #1 on it?

No. PET is not designed for heat. While it’s safe for cold and room-temperature drinks, microwaving PET containers can cause them to warp or release chemicals. Never microwave water bottles, soda bottles, or takeout containers marked with #1. Use only containers labeled microwave-safe - those are usually #5 (PP).

Why do some PET bottles have a different number inside the triangle?

They shouldn’t. If you see a different number - like 2 or 5 - inside the triangle on a bottle that looks like a water bottle, it’s likely a mistake or a different type of container. PET bottles always have #1. If you’re unsure, check the bottom for the word "PET" or "PETE" - that’s the official name.

Are PET bottles safe to reuse?

Technically, yes - but it’s not recommended. PET bottles are designed for single use. Reusing them can cause microcracks where bacteria build up, especially if you wash them with hot water or scrub them hard. Plus, the plastic breaks down over time. If you want to reuse a bottle, choose one made for multiple uses - like stainless steel or glass.

Does the number 1 mean the bottle is biodegradable?

No. PET is not biodegradable. It can take up to 450 years to break down in a landfill. Some companies market "compostable" PET, but those are usually blends with other materials and require industrial composting facilities. Standard PET bottles you buy at the store will not decompose in your backyard.

Next Steps: What to Watch For

The plastic industry is changing. New technologies like chemical recycling are starting to turn PET back into raw oil, which could revolutionize recycling. Companies like Ioniqa and Loop Industries are already doing it at scale. Meanwhile, governments in the EU, Canada, and parts of the U.S. are passing laws requiring minimum recycled content in bottles - some as high as 50% by 2030.For now, the number 1 remains your best friend in the fight against plastic waste. Know what it means. Recycle it right. And when you see someone toss a bottle without thinking - you’ll know exactly what they’re throwing away.