Who Dominates the Steel Industry Today?

Steel Production Comparison Tool

Compare Steel Production Volumes

See how your steel production volume compares to the world's top producers. Enter a volume in metric tons to visualize scale differences and environmental impact.

When you think about steel, you might picture skyscrapers, bridges, or cars. But behind every ton of steel is a handful of companies that control the global supply. The steel industry isn’t fragmented-it’s dominated by a small group of giants. These aren’t small factories or local players. They’re industrial powerhouses with billion-dollar operations, massive mines, and global supply chains. So who actually runs the steel world today?

The Top Three Steel Producers

As of 2025, three companies account for nearly 40% of the world’s crude steel output. The leader is China Baowu Steel Group. Headquartered in Shanghai, it was formed by merging China’s two largest steelmakers in 2020. In 2024, it produced over 130 million metric tons of steel-more than the entire output of the United States. It owns over 100 steel plants across China and has stakes in operations in Brazil, Australia, and Southeast Asia. Its scale is unmatched: one of its plants in Wuhan alone produces more steel annually than Germany’s entire industry.

Second is ArcelorMittal, based in Luxembourg. It’s the only non-Chinese company in the top three. Founded in 2006 after a merger between Arcelor and Mittal Steel, it operates in 18 countries. Its biggest plants are in India, Brazil, and Poland. ArcelorMittal produced about 72 million tons of steel in 2024. What sets it apart is its global reach: it sells steel to automakers in North America, construction firms in Europe, and infrastructure projects in Africa. It also owns major iron ore mines in Brazil and Canada, giving it control over raw materials.

Third is Hebei Iron and Steel Group (Hesteel), another Chinese giant. Though smaller than Baowu, it still produced over 65 million tons in 2024. It’s owned by the Hebei provincial government and operates 12 major steel mills. Hesteel is a key supplier for China’s infrastructure boom-bridges, high-speed rail, and new city developments. It’s also investing heavily in green steel technology, aiming to cut carbon emissions by 30% by 2030.

Why China Controls So Much

China produces over half of the world’s steel. That’s not an accident. It’s the result of decades of state-backed investment, cheap labor, and relaxed environmental rules in the early 2000s. By 2010, China had more steelmaking capacity than the rest of the world combined. Today, its government still directs investment through state-owned enterprises like Baowu and Hesteel. These companies don’t just chase profits-they follow national goals: self-sufficiency, export dominance, and infrastructure growth.

China’s dominance isn’t just about volume. It controls the supply chain too. Chinese firms own or invest in iron ore mines in Australia and Brazil. They control port facilities in Africa and Southeast Asia. And they’ve built the world’s largest fleet of bulk carriers to move raw materials. Even when steel is made elsewhere, the inputs often come from China-controlled sources.

What About the U.S. and Europe?

The U.S. has no single steel giant that rivals Baowu or ArcelorMittal. Instead, it’s made up of a few strong players. Nucor leads the pack with about 22 million tons of steel produced in 2024. What makes Nucor different? It uses electric arc furnaces that recycle scrap metal instead of coal-based blast furnaces. That makes it cheaper and cleaner. Nucor’s plants are mostly in the southern U.S., and it’s the only American company that consistently turns a profit even when global steel prices drop.

United States Steel (U.S. Steel) is older and bigger in name than in output. It produced around 10 million tons last year but has been losing market share. It still runs the last major blast furnace in Pittsburgh, but many of its plants are aging. In 2024, it was acquired by Japan’s Nippon Steel, which plans to invest $10 billion in modernizing U.S. Steel’s facilities over the next five years.

In Europe, the picture is more fragmented. SSAB in Sweden is a leader in green steel, using hydrogen instead of coal to reduce emissions. ThyssenKrupp in Germany still produces about 15 million tons but is struggling with high energy costs. The EU has imposed carbon tariffs on imported steel, which helps local producers-but only if they can afford the upgrades. Most European mills are still tied to coal and gas, making them less competitive than Nucor or Chinese firms using renewable power.

The Rise of India and Other Emerging Players

India is the second-largest steel producer after China. Tata Steel is the country’s biggest player, producing over 35 million tons annually. It owns plants in India, the Netherlands, and the U.K. Tata has been aggressive in buying up assets abroad, including a major stake in the U.K.’s Corus Group back in 2007. It’s also investing heavily in green hydrogen projects in Jamshedpur to replace coal in its furnaces.

JSW Steel, another Indian giant, grew 18% last year and now produces over 20 million tons. It’s building a new $12 billion plant in Karnataka, one of the most advanced in the world. Unlike older mills, JSW’s facility uses AI to monitor furnace temperatures and predict maintenance needs-cutting downtime by 25%.

Other countries are trying to catch up. Indonesia, backed by Chinese investment, is building massive steel plants to process its own nickel ore. Turkey’s Erdemir is a major exporter to Europe and the U.S., producing over 12 million tons. Brazil’s CSN is another key player, supplying steel to Latin America and exporting to Asia.

What’s Changing the Game Now?

It’s not just about how much steel you make anymore. It’s about how you make it. Climate policies are forcing change. The EU’s Carbon Border Adjustment Mechanism (CBAM) now charges extra fees on steel made with coal. The U.S. Inflation Reduction Act gives tax credits to mills using renewable energy. China’s 2060 carbon neutrality goal means its biggest producers must cut emissions-even if it costs billions.

That’s why green steel is the new frontier. Companies like SSAB, ArcelorMittal, and Nucor are racing to build hydrogen-based production lines. SSAB’s pilot plant in Sweden already produces steel with near-zero emissions. Nucor is testing hydrogen injection in its electric furnaces. Baowu is investing in carbon capture tech for its blast furnaces.

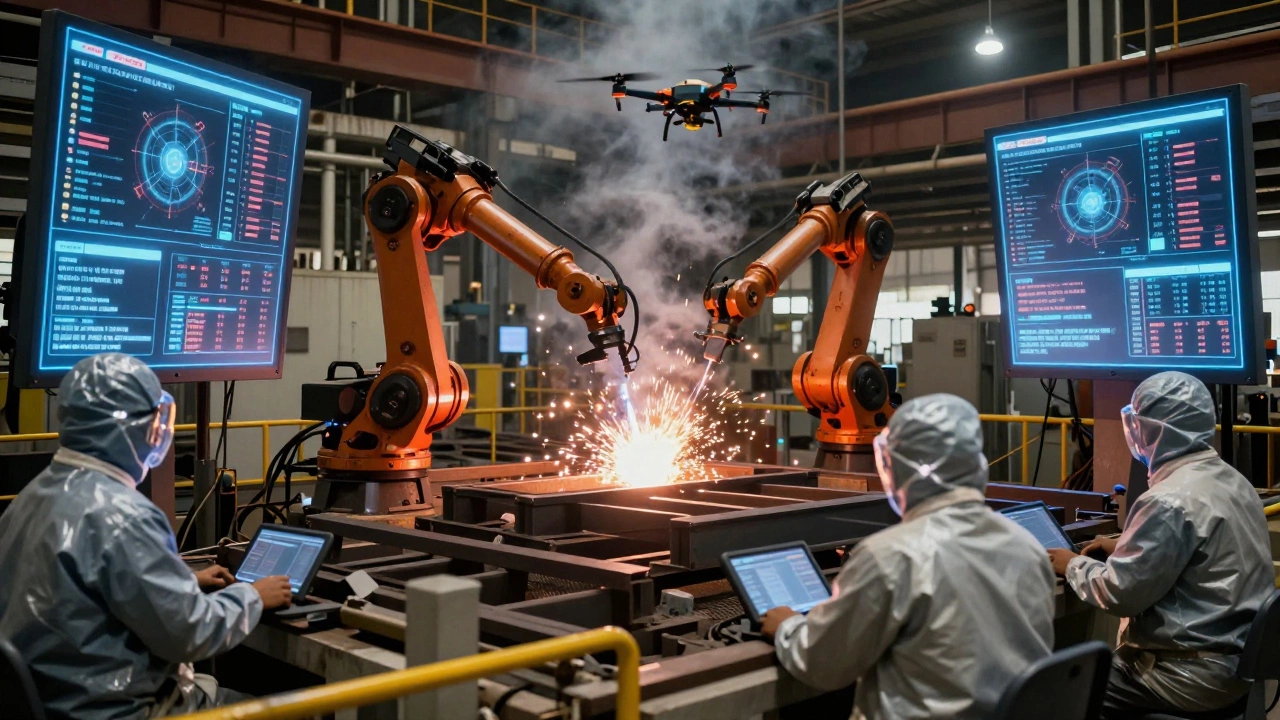

Technology is also reshaping production. AI now predicts steel quality before出炉 (出炉 =出炉), reducing waste. Robotics handle dangerous tasks like slag removal. Drones inspect blast furnaces instead of workers climbing into hot, toxic spaces.

Who Will Dominate in 2030?

China will still lead in volume-but its dominance may weaken. Rising labor costs, aging infrastructure, and stricter environmental rules are slowing growth. Baowu and Hesteel are expanding overseas, but political pushback is growing. The U.S. and EU are pushing for reshoring, offering subsidies to build new mills.

India is the wild card. With cheap labor, growing domestic demand, and government support, it could overtake Japan and Germany by 2030. Tata and JSW are building the next generation of steel plants-clean, smart, and efficient.

And then there’s the U.S. If Nucor and the newly acquired U.S. Steel can scale up green steel production fast enough, they could reclaim a bigger share of the global market. The key will be access to cheap renewable energy and government contracts.

The steel industry is no longer just about size. It’s about speed, sustainability, and smarts. The winners in the next decade won’t be the ones with the biggest furnaces-they’ll be the ones with the cleanest, smartest, and most adaptable operations.

Who is the largest steel producer in the world?

As of 2025, China Baowu Steel Group is the world’s largest steel producer, with an annual output of over 130 million metric tons. It surpassed ArcelorMittal in 2020 after merging with other Chinese state-owned steel companies and now produces more steel than the entire United States.

Is ArcelorMittal still a major player in steel?

Yes. ArcelorMittal is the second-largest steel producer globally, producing around 72 million tons in 2024. It’s the only non-Chinese company in the top three and operates in 18 countries. Its strength lies in its global supply chain, owning mines in Brazil and Canada, and supplying major markets in Europe, North America, and Africa.

Why is China so dominant in steel production?

China dominates because of decades of state investment, low labor costs, and relaxed environmental regulations in the past. Its government directs production through state-owned enterprises like Baowu and Hesteel to meet national infrastructure goals. China also controls key parts of the supply chain, including iron ore mines and shipping routes, giving it unmatched leverage.

Which U.S. company produces the most steel?

Nucor is the largest U.S. steel producer, making about 22 million tons annually. It uses electric arc furnaces that recycle scrap metal, making it more cost-effective and environmentally friendly than traditional blast furnaces. Nucor is also the only American company that consistently profits even during global steel downturns.

What is green steel and who is making it?

Green steel is produced using hydrogen or renewable energy instead of coal, cutting carbon emissions by up to 95%. SSAB in Sweden is the leader, with a commercial-scale hydrogen-based plant already operating. Nucor, ArcelorMittal, and Baowu are also investing heavily in green steel technology to meet climate regulations and customer demand.