Understanding Manufacturing's Role in Government Schemes

Manufacturing stands as a cornerstone of our global economy, weaving together numerous threads in the fabric of government policy. Its importance extends into the corridors of power, influencing not just economic strategies but also the very structure of governance itself. As nations aim to bolster economic growth, understanding where manufacturing fits within the government can offer crucial insights.

Many people wonder exactly what department oversees manufacturing activities. The answer is not always straightforward, as government structures can differ from one country to another. Yet, the nature of assistance and regulatory oversight provided to manufacturing typically hinges on certain key departments, often those related to industry, trade, or economic development.

By exploring these governmental frameworks, we reveal not only how manufacturing aligns with them but also how it shapes policy making that impacts our everyday lives. So, dive into the layers of bureaucracy where a pivotal sector like manufacturing sits, and discover how it steers the wheels of policy and practice.

- The Role of Manufacturing in Government

- Key Departments Overseeing Manufacturing

- Government Initiatives Impacting Manufacturing

- How Departments Collaborate with Industry

- The Economic Influence of Manufacturing Policies

- Future Trends in Government Manufacturing Schemes

The Role of Manufacturing in Government

Manufacturing is like the heartbeat of a nation's economy. It's no wonder, then, that governments around the world place a high emphasis on this sector. This critical industry not only supplies the goods and products used daily but also supports millions of jobs, contributing significantly to national GDP. In Australia, for instance, the manufacturing industry employs over 900,000 people and it's projected to grow as investment in advanced technologies increases. Manufacturing is undeniably interwoven with governmental objectives, from employment to innovation, and energy solutions to urban development.

The integration of manufacturing within government schemes is vital for fostering stable economic growth. Departments dedicated to trade and industry often spearhead policies aiming to enhance the competitiveness of this sector. By introducing tax incentives and subsidies, governments encourage manufacturing firms to innovate and expand. This, in turn, drives job creation and fuels economic well-being. Around the globe, nations like Germany and South Korea have set benchmarks for integrating government policies and manufacturing prowess. Citing a reliable source, an executive remark from the World Economic Forum stated,

"Manufacturing is more than a producer; it is a blueprint for development."

Government's Strategic Influence

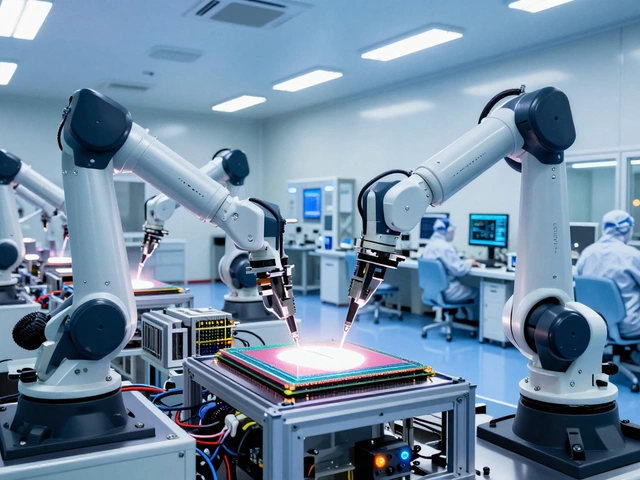

Governments wield significant influence over manufacturing strategies by embedding them within broader economic policies. They do this not merely as regulators but as strategic partners fostering innovation. Public-private partnerships are formed, and these collaborations often lead to transformative results. The manufacturing sector benefits directly from these associations, offering a platform where innovation translates to profitability and productivity. Strong governmental backing has seen nations adopt technology-driven manufacturing solutions, strengthening industrial frameworks and advancing digital manufacturing.

The ripple effect of government involvement extends beyond tangible outputs, permeating sectors such as research, education, and technical training. By investing in these areas, governments ensure a skilled workforce ready to meet the demands of modern manufacturing. Educational programs are tailored to match industry requirements, preparing future generations for technologically advanced roles. In some cases, nations have established specialized manufacturing hubs to foster growth in specific areas, be it aerospace, automotive, or biotechnology. This holistic approach underlines the symbiotic relationship between manufacturing and government, one that is integral to national progress.

Key Departments Overseeing Manufacturing

Manufacturing is a dynamic and multifaceted sector that lies at the heart of many government policies around the world. Its oversight typically falls under a variety of departments, each playing its own vital role in shaping the industry's trajectory. These departments often align with industry, trade, commerce, or economic development. In Australia, for instance, the Department of Industry, Science and Resources takes the lead in promoting innovation and investment in manufacturing, aiming to boost jobs and advance technological prowess.

The involvement of the Department of Industry doesn’t end with supportive policies. They actively engage with local manufacturers to ensure responsiveness to global trends and challenges. This includes anything from incentivizing green manufacturing practices to facilitating trade agreements that open new markets for Australian-made products. Such synergetic initiatives are pivotal, considering the global competition in sectors like automobiles and electronics, where innovation equals survival.

Industry and Trade Departments

Departments specifically dedicated to trade and commerce are equally significant in manufacturing. Their focus often lies in eliminating barriers to trade, whether these are tariffs or logistical challenges. In India, the Ministry of Commerce and Industry works fervently to balance the scales of global trade, ensuring Indian manufacturers have equal footing on the international stage. At times, these offices work hand in hand with diplomatic efforts to secure favorable terms for their country's products - a delicate dance of politics and economics.

"Effective government policies have always been the backbone of manufacturing growth, supporting sectors and driving innovation," noted Dr. Craig Emerson, a former Australian Trade Minister, in an industry forum.

Economic Development and Investment Promotion

Beyond these, economic development departments often seek to create an ecosystem where manufacturing thrives. This is accomplished through infrastructure development, education, and upskilling initiatives, which are vital for sustaining growth. Training programs are tailored to equip the workforce with necessary skills, thereby aligning with the evolving demands of the manufacturing landscape. For example, Canada's Innovation, Science and Economic Development department emphasizes the uptake of advanced technologies like AI and IoT in traditional manufacturing processes to ensure competitiveness.

Additionally, some countries even form specialized clusters or regions aimed at fostering manufacturing innovation. Known as manufacturing hubs, these clusters aim to generate synergies by situating suppliers, customers, and labor pools close to each other. This strategy has been notably successful in Germany, where clusters like Baden-Württemberg lead in automotive excellence, backed by government support and strategic investment.

Finally, these departments don't work in isolation. Their success is inherently tied to collaboration with private sectors, educational institutions, and international partners. As such, the orchestration behind manufacturing oversight is both an art and science, aligning policy with purpose, and ensuring the sector not only survives but thrives.

Government Initiatives Impacting Manufacturing

In recent years, numerous governments around the world have upped their game in supporting the manufacturing sector through a variety of initiatives. These initiatives aim to bolster industrial capacity, enhance competitiveness, and drive innovation. The strategy behind these initiatives often involves multi-faceted approaches, including tax incentives, subsidies, and research grants. As such, manufacturers must stay informed about these opportunities to maximize their benefits. For instance, one popular approach involves offering tax credits, which effectively reduce taxable income that companies have to report, thereby freeing up capital that can be reinvested into the business.

The need for a strong manufacturing base is not just economic but strategic. With global supply chains often facing disruptions, countries aim to reduce dependencies by incentivizing local production. Government policies may provide grants for upgrading technology, thus enabling factories to adopt cutting-edge tools like automation and AI. Programs also frequently target specific sectors such as automotive, aerospace, or consumer goods, often reflecting current global trends or national priorities. For example, green energy technology is currently receiving a great deal of legislative attention as countries aim to meet international climate commitments.

Many governments are also focusing on workforce development within the manufacturing sector. Skills-training programs funded by public money aim to ensure that the workforce is equipped with modern skills. These programs help bridge the gap between traditional manufacturing skills and the increasingly tech-driven abilities needed today. Interestingly, partnerships between educational institutions and manufacturing companies are crucial in this context, providing real-world insights and practical skills to students and workers alike. An example of this is the collaboration between technical colleges and local manufacturers in Germany, which serves as a model for other nations.

"Governments that invest in manufacturing are not just investing in factories or output; they are investing in communities and in the future of their own economies," says economist John Prescott.

Statistical data often highlights the impacts of these schemes. For instance, a notable increase in manufacturing output and employment can usually be observed in regions where comprehensive government initiatives are in place. According to reports, countries with proactive policies often experience faster industrial growth compared to those with minimal governmental involvement. The role of government can indeed make or break a region's manufacturing prospects.

The impact of government initiatives on manufacturing is multifaceted, deep, and far-reaching. As the world continues to evolve at a rapid pace, so too must the policies that support one of the most crucial sectors of any economy. Businesses within this sphere are encouraged to keep abreast of policy changes in order to stay competitive and take advantage of all opportunities presented by these schemes.

How Departments Collaborate with Industry

Collaboration between government departments and the manufacturing industry is a dynamic and intricate process that significantly impacts economic growth and policy development. At its core, this partnership is designed to create a synergistic relationship where both parties benefit — the government encourages economic expansion, while industries receive the support they need to thrive. One of the main avenues for collaboration involves regulatory frameworks that are established to ensure fair trade practices, standardization of products, and the adherence to environmental regulations. Through these regulations, governments strive to create a level playing field that benefits society while simultaneously promoting industrial innovation.

Innovation, in particular, is a key focus for both government departments and the industry. Departments often offer incentives such as tax breaks, grants, and subsidy schemes to encourage industries to invest in cutting-edge technologies and sustainable practices. For instance, the Australian government has rolled out various initiatives under its Industry Growth Centres program, which includes sectors like advanced manufacturing. These initiatives are designed not only to stimulate local manufacturing but also to align national industrial capabilities with global market demands. These efforts have seen significant traction, showcasing the critical role of governmental support in the thriving of local industries. It's interesting to note that governments frequently engage with industry representatives through committees or advisory boards to better understand the needs and challenges facing the manufacturing sector.

Such engagement often extends to public-private partnerships (PPPs) where the risk and investment are shared between government and industry. These partnerships pave the way for significant infrastructure projects, research and development collaboration, and joint ventures that might not feasible through independent actions by either party. As reported by the World Economic Forum, "Effective government-industry collaboration can accelerate innovation and lead to faster, broader adoption of breakthrough technologies," highlighting the mutual benefits of such efforts. An excellent example of this can be seen in the renewable energy sectors, where government support has facilitated the industry shifts towards greener practices, effectively promoting environmental sustainability along with economic growth.

Another crucial aspect of collaboration involves the data-sharing agreements that empower industries with the necessary information for strategic planning. Governments collect vast amounts of data, including economic forecasts, consumer trends, and international trade figures, which can be invaluable to industrial forecasting and strategic alignment. Data access enables industries to anticipate changes, adapt quickly, and maintain competitiveness in the global arena. Beyond financial or strategic support, government departments often act as intermediaries in fostering international trade relationships by assisting industries in navigating the complex web of international regulations and tariffs. This kind of support is crucial for manufacturing companies looking to expand beyond domestic borders.

In summary, the interplay between government departments and the manufacturing industry is a cornerstone of contemporary economic policies. Whether through regulation, innovation incentives, partnerships, or data sharing, these collaborations play a pivotal role in shaping a resilient and forward-looking manufacturing sector. As industrial demands evolve, so too will the strategies and frameworks that underpin these critical collaborations.

The Economic Influence of Manufacturing Policies

Manufacturing policies hold a profound sway over a nation's economy, touching everything from job creation to technological advancements. Historically, countries renowned for robust manufacturing, like China and Germany, have seen significant contributions to their GDP from this sector. The ripple effects of such policies can stimulate economic activity, pouring resources back into public services, reducing unemployment, and even nurturing local innovation. By focusing governmental efforts on enhancing manufacturing capabilities, nations can tap into this powerful economic engine.

One of the core benefits of supportive manufacturing policies is the boost in employment opportunities. Large-scale factories and small manufacturing units alike need skilled and semi-skilled workers, opening doors for a diverse array of jobs. This increase in employment doesn't just benefit individuals but fuels economic consumption, as working citizens have more disposable income to spend on goods and services, thereby invigorating different sectors of the economy. Moreover, manufacturing often requires a supply chain of smaller businesses, amplifying the economic impact through these allied industries.

The development and implementation of manufacturing policies also spur technological innovation. Historically, manufacturing sectors have been at the forefront of adopting new technologies, such as automation and robotics. Policies that encourage research and development within manufacturing can lead to breakthroughs that serve wider industries. For instance, advancements in 3D printing, driven initially by manufacturing demands, have now permeated sectors such as healthcare and aerospace. The knock-on effect is increased productivity, lower costs, and more innovative end products that appeal to global consumers.

When government schemes provide subsidies or tax incentives to the manufacturing sector, they make it more competitive on an international scale. Considerations like reducing energy costs through efficient practices or funneling investments into green technologies can make national products more favorable in the global market. This not only improves trade balances but can also provide leverage in international negotiations, boosting a nation's standing on the world stage. As noted by the World Bank, "Manufacturing remains a vital engine for economic growth, trade, and productivity."

Environmental considerations are increasingly becoming a focal point of manufacturing policies. With climate change at the forefront of global challenges, governments are looking to steer manufacturing towards more sustainable practices. Encouraging eco-friendly innovations not only aligns with modern values but can also lead to long-term savings and a healthier planet. Policies aimed at reducing carbon footprints in manufacturing can result in industries evolving towards sustainability, setting new norms that ripple across sectors. This intersection of environmental stewardship and economic growth is an exciting frontier of modern policy-making.

In conclusion, the intertwining of government schemes with the manufacturing sector is about more than immediate economic gains. It's about creating a foundational backbone for future growth and resilience. By understanding and harnessing the power of manufacturing policies, countries can better navigate the complexities of global markets. As consumers, workers, and innovators benefit from these policies, the larger economic tapestry grows richer, weaving together diverse threads of progress, sustainability, and prosperity.

Future Trends in Government Manufacturing Schemes

As the manufacturing landscape rapidly evolves, governments around the world are strategizing to keep up with these changes, crafting schemes that are not only innovative but also sustainable. Technology is one of the driving forces behind these transformations, with digitization, automation, and artificial intelligence reshaping factories. Governments are now pushing for smart manufacturing by investing heavily in the digital transformation of industries. This push not only enhances production efficiency but also reduces errors and operational costs. Such trends signify a shift towards an Industry 4.0 model, where integration of advanced technology becomes the norm.

Environmental considerations are also at the forefront of future manufacturing schemes. With global warming and climate change becoming increasingly urgent issues, governments are implementing stricter regulations targeting carbon emissions and waste management. Green manufacturing practices are being heavily incentivized. Through grants, tax benefits, and subsidies, businesses are encouraged to adopt eco-friendly technologies and processes. This not only helps protect the environment but also opens new markets for green products, catering to the rising demands of eco-conscious consumers.

Another notable trend is the reshoring of manufacturing processes. In response to recent disruptions in global supply chains, many governments have introduced policies encouraging companies to relocate their manufacturing units back home. By providing low-interest loans and grants, governments aim to create jobs and boost local economies. This trend towards localizing supply chains could lead to a more resilient and stable economy, reducing reliance on international trade routes that can be affected by geopolitical tensions or pandemics.

The focus on workforce development is also a significant trend. As manufacturing becomes more complex, the demand for skilled labor increases. Governments are partnering with educational institutions to develop training programs that equip workers with necessary technical skills. Apprenticeship opportunities and upskilling initiatives are being ramped up to meet the industry's evolving demands. Ensuring a competent workforce helps sustain economic growth and maintain global competitiveness.

Manufacturing schemes are also embracing customization and flexibility in production. The age of mass production is being complemented, if not replaced, by on-demand production capabilities. This trend is powered by advancements in 3D printing and other adaptable manufacturing technologies. Businesses are now equipped to personalize products faster and with greater precision, meeting consumer demands for unique, tailor-made solutions. Government support is crucial in this shift, offering incentives for research and development in these areas.

Finally, considering the rapid globalization and collaborative efforts among nations, international cooperation and agreements are part of futuristic manufacturing trends. These initiatives pave the way for standardizing practices and sharing resources and innovations globally. Countries are working together to tackle challenges such as cybersecurity threats and intellectual property rights, ensuring a smoother and more equitable global manufacturing ecosystem.

"In this age of digitalization, the capacity to innovate will determine the sustainability and success of our manufacturing sector," said Dr. Emily Cross, an expert in industrial policies.

This ever-dynamic field of manufacturing holds the promise of tomorrow's innovations, driven by a blend of technology, sustainability, and adaptive policies. For stakeholders, understanding and navigating these trends is key to staying competitive and thriving in an environment that's continually being reshaped by technological progress and resource realignment.