Why Do 90% of Startups Fail? Real Reasons Behind Manufacturing Startup Failures

Manufacturing Startup Unit Economics Calculator

Calculate Your Manufacturing Profitability

Determine if your manufacturing business is truly profitable. The article reveals that many startups fail because they don't track unit economics down to the rupee. This calculator helps you identify critical risks before you invest in equipment.

The article emphasizes: "If your profit per unit is under ₹500, you're not a business—you're a hobby with debt."

Gross Profit Per Unit

₹0.00

Net Profit Per Unit

₹0.00

Total Monthly Profit

₹0.00

Monthly Marketing Cost

₹0.00

This calculator shows what you're actually earning after all costs and returns.

Most people think startups fail because they run out of money. That’s only half the story. In manufacturing, where you need machines, materials, and skilled labor from day one, running out of cash is just the symptom-not the cause. The real reasons why 90% of manufacturing startups die within five years are deeper, messier, and completely avoidable if you know what to look for.

They build something nobody wants

Too many manufacturing founders fall in love with their product before they’ve talked to a single customer. I’ve seen it a dozen times: a guy spends $80,000 building a custom CNC machine for small workshops, only to find out that 90% of those workshops already have older machines they’re happy with, and the rest don’t have the budget to upgrade. He didn’t test demand. He assumed need. In manufacturing, you can’t pivot like a SaaS startup. You can’t just delete code and rewrite it. Once you’ve ordered tooling, signed leases, and hired operators, you’re locked in. That’s why the best manufacturing startups start with pre-orders-not prototypes. One company in Gujarat started by taking 50 advance payments for custom metal brackets before they even bought their first press. That $15,000 in cash gave them the green light to invest in equipment. No guesswork. No debt.They underestimate the supply chain

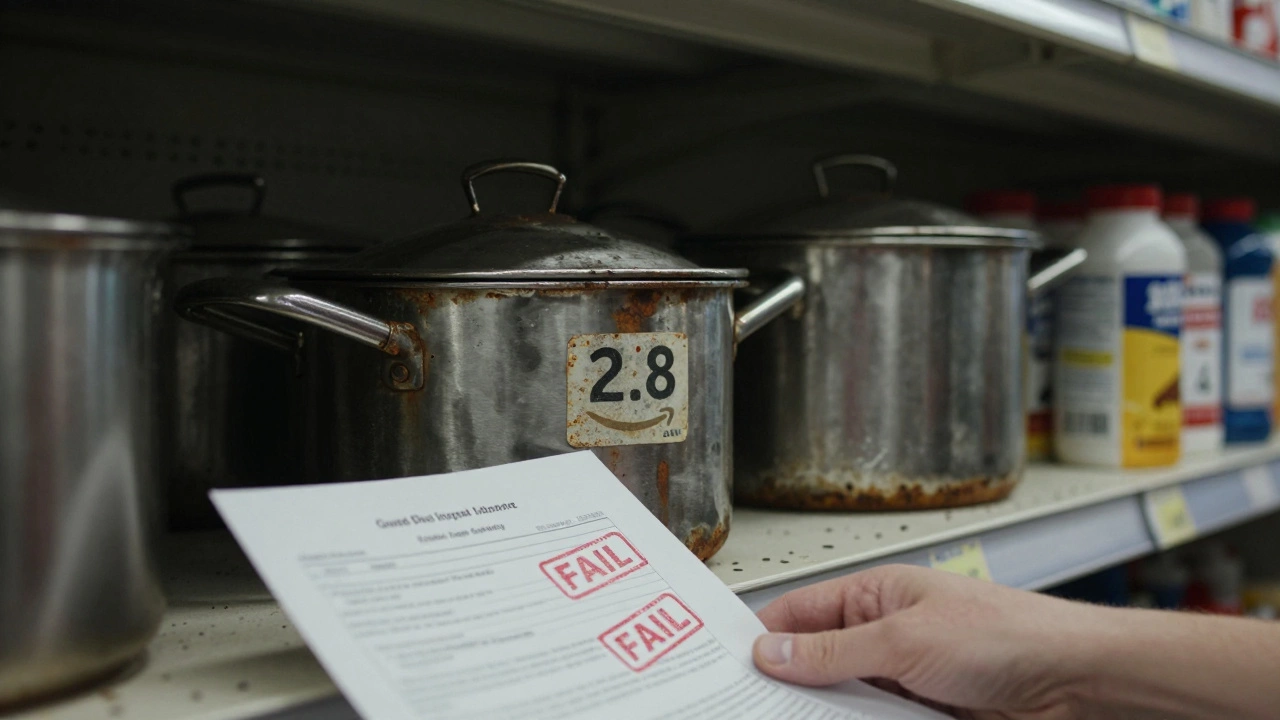

You think you’re buying raw materials? You’re really buying reliability. A single delayed shipment of aluminum billets can shut down your entire production line for weeks. And if your supplier cuts corners on quality, you’re not just losing money-you’re losing trust. I worked with a startup in Tamil Nadu that made stainless steel cookware. They saved 12% on costs by switching to a cheaper supplier in Bangladesh. Three months later, 40% of their pots developed rust spots. Customers returned them. Their Amazon rating dropped to 2.8. They spent the next year rebuilding their reputation-and lost 60% of their sales. Manufacturing startups need at least two verified suppliers for every critical component. Not just for cost. For survival. And don’t trust a supplier just because they’re cheap. Check their delivery history. Ask for batch certificates. Visit their facility. If they won’t let you in, walk away.They ignore compliance and certifications

In manufacturing, paperwork isn’t bureaucracy-it’s your license to operate. A startup making food-grade plastic containers in Uttar Pradesh got shut down because they didn’t have FSSAI certification. They thought they could sell to local retailers without it. They couldn’t. The retailer got fined. The startup got blacklisted. Every product has rules. Medical devices need ISO 13485. Electrical components need BIS certification. Even simple items like metal shelving need safety ratings. Skipping these isn’t a shortcut-it’s a time bomb. And regulators don’t care if you’re a startup. They care if your product is safe. The smart ones build compliance into their roadmap from Month 1. Budget for certifications. Hire a consultant if you have to. It costs $5,000 upfront, but it saves you $500,000 in recalls, lawsuits, and lost customers later.

They think scaling means hiring more people

A common mistake: you get your first 10 orders, you’re excited, so you hire three more workers. Then you get 20 orders, so you buy another machine. Then you get 50, and suddenly you’re paying $15,000 a month in salaries and rent, but your profit margin is shrinking. Scaling in manufacturing isn’t about adding people-it’s about adding systems. One founder in Pune doubled his output without hiring anyone. He redesigned his assembly line to reduce movement. He switched from manual measuring to laser gauges. He automated his packaging with a $3,000 robot arm. Output went up 80%. Labor costs stayed flat. If you’re hiring before you’ve optimized your process, you’re not scaling-you’re inflating your burn rate.They don’t track unit economics

You sell a metal cabinet for ₹4,500. Your materials cost ₹2,200. Labor is ₹800. Shipping is ₹300. That leaves ₹1,200 profit. Sounds good, right? But what if you spend ₹20,000 a month on marketing? What if 30% of your orders get returned because the hinges break? What if you have to replace 15% of your inventory because of storage damage? Most manufacturing startups don’t track their true cost per unit. They look at gross revenue and think they’re doing fine. They’re not. One startup in Jaipur was selling 500 units a month at ₹5,000 each. They thought they were making ₹25 lakh in revenue. But after factoring in returns, warranty claims, and logistics delays, their net profit was ₹18,000 a month-less than what they paid their manager. Know your unit economics down to the rupee. Every cost. Every return. Every delay. If your profit per unit is under ₹500, you’re not a business-you’re a hobby with debt.

They don’t build relationships with distributors

In manufacturing, you don’t sell directly to end customers unless you’re a giant. You sell to distributors, wholesalers, retailers. But most founders treat them like transactional partners. One company in Ludhiana made custom door handles. They had great products. But they didn’t offer credit terms. Didn’t provide marketing materials. Didn’t respond to emails within 48 hours. Their distributors switched to competitors who made it easy. Distributors don’t just move product-they give you market access. Treat them like partners. Offer them exclusive regions. Give them co-branded flyers. Pay them on time. Send them new samples every quarter. They’ll fight for you.They don’t plan for the long game

Startups fail because they’re always in firefighting mode. They’re chasing the next order, fixing the next machine breakdown, dealing with the next supplier issue. They never step back to ask: Where will we be in three years? The survivors build for the future. They invest in R&D even when cash is tight. They patent designs. They train their team to cross-train. They diversify their product line before they’re forced to. One company in Ahmedabad started with aluminum profiles. Then they added custom cut-to-length services. Then they started offering design support to architects. Now they’re the go-to supplier for mid-sized construction firms. You don’t need to be the biggest. You just need to be the most adaptable.What to do instead

If you’re starting a manufacturing business, here’s what actually works:- Get paid before you build. Take pre-orders. Use them to fund your first run.

- Test your product with 10 real customers before spending more than ₹50,000 on equipment.

- Map your supply chain like a military operation-know your backup for every critical part.

- Build compliance into your budget. Don’t wait until you’re caught.

- Automate before you hire. Optimize before you scale.

- Track every rupee of cost per unit. If your profit is under ₹500, fix it or pivot.

- Partner with distributors like family-not vendors.

- Set a three-year vision. What will you be making in 2028? Start building toward it now.

Manufacturing isn’t glamorous. But it’s real. And the ones who survive? They don’t have better ideas. They just avoid the same mistakes over and over.

What’s the #1 reason manufacturing startups fail?

The #1 reason is building a product nobody wants to buy. Many founders assume demand exists because they like the idea. But in manufacturing, you need pre-orders, pilot customers, or signed contracts before investing in equipment. Without real demand, even the best product becomes expensive inventory that rots.

Can a manufacturing startup survive with low funding?

Yes-but only if you start small and scale with revenue, not debt. Use contract manufacturing for your first runs. Rent equipment instead of buying. Partner with local workshops to share space. Focus on one product, one customer type, and one distribution channel. Many profitable manufacturing businesses in India started with under ₹2 lakh in seed money and grew slowly by reinvesting profits.

How important are certifications for small manufacturers?

Critical. Even small manufacturers need basic certifications like BIS for electronics, FSSAI for food contact materials, or ISO 9001 for quality systems. Without them, you can’t sell to retailers, government tenders, or big brands. Some certifications cost less than ₹10,000 and take under 30 days. Skipping them is like driving without a license-eventually, you’ll get caught.

Is outsourcing production a good idea for startups?

It’s one of the smartest moves. Outsourcing lets you test demand without buying machines. You can work with local workshops in clusters like Tiruppur for textiles or Moradabad for metalware. Once you hit consistent demand, you can bring production in-house. Many successful brands like Boat and Mamaearth started by outsourcing before building factories.

What’s the best way to find reliable suppliers?

Don’t rely on Alibaba or just price. Visit suppliers in person. Ask for samples. Check their delivery history over the last 6 months. Talk to their other customers. Use local industry associations-like the All India Manufacturers Organization-for referrals. A supplier who shows up on time, every time, is worth 20% more than the cheapest one.

How long does it take for a manufacturing startup to become profitable?

Most take 18 to 36 months. The fastest ones-those with pre-orders, low overhead, and simple products-hit profitability in 12 months. The slow ones spend two years burning cash trying to scale too fast. Don’t compare yourself to tech startups. Manufacturing is a marathon, not a sprint.